Natural gas hydrate (NGH) contains tremendous

quantities of methane gas and tends to be a significant future energy source if

it can be economically and effectively produced (Milkov, 2003). In recent

years, governments and commercial companies from different countries show

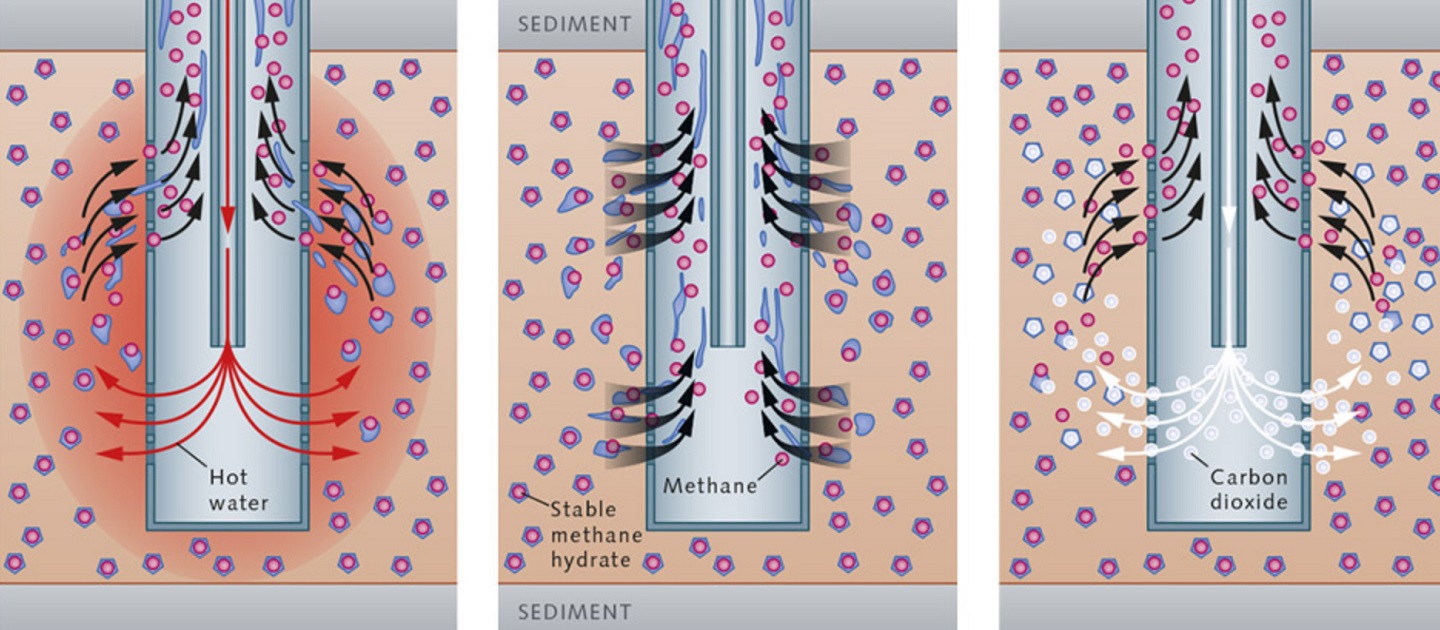

increasing interests on NGH trial production (Rong, 2016). Although several

methods, including depressurization, thermal stimulation, and inhibitor

injection, are being considered for production of gas and water from

hydrate-bearing formations, depressurization seems to gain much more acceptance

and recognition than others (Moridis, 2011; Zhao, 2015; Zhang, 2019), which

employ a wellhole as production channel for fluid flowing and is very similar

to the conventional oil and gas production style in traditional oil and gas

industries.

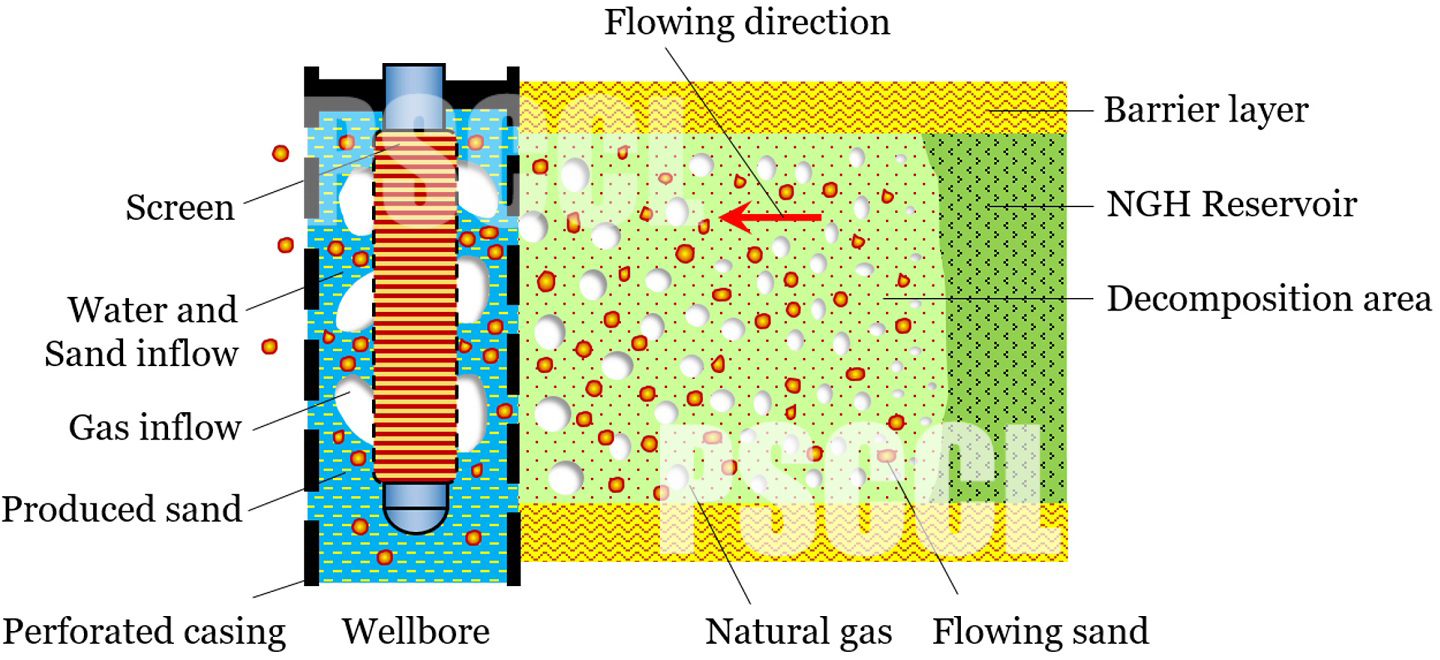

Sand production is one of typical engineering

problems during the depressurization production of NGH, due to the dissolution

of hydrate and decrease of sediment strength (Moridis, 2011). The issue of sand

production has been reported in hydrate production in Messoyakha (Grover,

2008), Mallik in Canada (Yamamoto, 2008), Alaska in USA (Lu, 2011), Nankai

Trough of Japan (Saeki, 2014; Yamamoto, 2019) and Shenhu sea area of China (Li,

2018). The hotspot of hydrate production in recent years is the trial

production case in Shenhu of China, the formation sand of which contain silty

clay with content as high as more than 25%, even up to 35%. The medium size of

the sand varies from 10μm to 35μm, which is extremely smaller than that of

traditional oil and gas formation(Li, 2019; Dong, 2018). The extremely high

content of clay and fine particle size are the main causes for media plugging

and productivity damage, which improve the difficulties for effective sand

control in gas hydrate production (Dong, 2017, 2018; Li, 2019).

This image is from Baidu or Bing, just for public usage.

Sand production and sand control in gas

hydrate reservoirs are obviously different from those in traditional oil and

gas reservoir. During the depressurization, the solid hydrate will dissolute

and decompose into gas and water (Zhao, 2015). Meanwhile, the sediment strength

will decrease dramatically leading to formation deformation and sand collapse

and migration with fluid flow (Cohen, 2019). The phase transformation affects the law of sand

production with complicated mechanisms (Moridis, 2011; Chen, 2020), which is

rarely observed in oil and natural gas reservoir. For sand control in gas

hydrate reservoir, high content of clay will aggravate the fines plugging of

sand retention media and cause high productivity loss (Dong, 2017, 2018; Li,

2019). Correspondingly, the extremely fine sand need corresponding thin slot

width or sand retaining accuracy (SRA) to control effectively, which also leads

to low deliverability of screen media (Andiappan, 2014). As well known, the medium

size of formation sand in oil and gas reservoir is about 50-200μm, much larger

than that in gas hydrate reservoir in the Shenhu area. The widely used screen

products in traditional oil industries are not applicable also. It’s of great

significant to re-investigate the behavior of highly argillaceous fine sand

blocking the screen media with corresponding SRA.

For the purpose of solving sanding problem in NGH production, efforts and studies have been done to sand production and control. Uchida (2016, 2019) developed a comprehensive numerical model and analytical formulation to predict the rate of sand production in gas hydrate reservoirs. The model considers the factors of stress reduction, sediment shear deformation, grain detachment and migration during depressurization production. Yan (2018), Dong (2019), Zhu (2020) also performed numerical simulations of sand and gas production for NGH reservoirs with different considerations and conditions and analyzed the law of sand production. Meanwhile, other researchers (Lu, 2019; Cohen, 2019; Ding, 2019) conducted experiments to simulate the sand production process during gas hydrate depressurization production. The above mentioned numerical and experimental studies improve the further cognition of sanding problem during gas hydrate production. The results illustrate that sand migration and production is one of the key problems not to be ignored, and effective sand control strategies are essentially necessary for NGH reservoir exploitation.

Sand control is not a new story in traditional oil and natural gas industries. So many studies have been carried out to control the sand production from loose sandstone reservoirs (Mondal, 2012; Agunloye, 2014; Mahmoudi, 2016; Dong, 2016, 2017;Wu, 2017; Velayati, 2018;Ma, 2020), which mainly concerns the sand control methods, screen development, design model and method, media plugging, evaluation and selection, and downhole performance. Among these researches, Lau (1997), Dong (2011,2017), Andiappan (2014) and Ma (2020) analyzed the sand bridge plugging mechanism and permeability performance of screen media by experimental simulations. The process of sand retaining is really the process of the media plugging, during which the media permeability decreases rapidly in the early stage of displacement and achieve stable status at a certain time. Relatively speaking, just in last several years, sand control in gas hydrate reservoir gains enough interest and attention, especially after the trial production of NGH in Japan and China. Lee (2013) performed experiments to simulate the depressurization production process of gas hydrate and sand production, and visually observe the sand production and screen performance. It was found that the amount of sand collected after the experiment was less than 0.012% of the total mass of the sediment samples. Aiming to the supper fine sand control, Li (2017,2020) firstly put forward a gravel sizing method for sand control packing named "Hold coarse while eliminate fine particle" for the clayey hydrate-bearing formations. This model depend on particle size distribution of sand from NGH Reservoirs and the assumptions that the formation sand could be divided into two components, which are coarse component and fine component. The similar viewpoint was applied in the mesh size design of sand control screen for NGH production, achieving the balance between retaining coarser particles and avoiding screen blockage by the relatively fine particles. Li (2019) also developed a sand control system and screen design method for clayey silt hydrate reservoirs. Nodal analysis method was used to determine the formation sanding rate, proper sand-control gravel size, and risk position of borehole blockage. He (2018) analyzed the sand control method of gravel-packing for China South Sea and suggested to select gravel size of 0.2-0.25mm and the thickness of 40mm for sand control parameters. To preliminarily investigate the mechanism and law of sand retaining in NGH reservoir, Dong (2019) carried out series of experiments using different types of screen and media samples with SRA of 20, 40 and 60μm. The results show that the duration time and degree of media plugging highly depend on the media structure and flow parameters. Three macroscopic sand retaining mechanisms were put forward, which involved sand entrainment by the gas-liquid flow, sand bridging inside the screen, and sand separation bridging outside the screen. Ding (2019) also conducted some innovative studies on sand production and control particularly for NGH reservoirs in the Liwan area of South China Sea. The experimental results recommended a screen design criterion that the median grain size of the gravel should be 11 times greater than that of the formation sand.

General speaking, the researches on sand control mainly focus on the sand problem in traditional sandstone reservoirs. The above-mentioned innovative research on sand control in NGH reservoirs is still at the beginning stage. These researches mainly concern the evaluation of sand control method, design of screen size and gravel size, which provided an elementary solution for sand-production control in particular NGH reservoirs. Also, these researches show the basic sand retaining principle and the law of gravel and screen design, most of which are microscopical and qualitative. In fact, to control highly argillaceous fine sand successfully during NGH production, microcosmic retaining mechanism and behavior of screen media are also key foundation for evaluation and design of proper sand control method, which is just what the present research concern seldom. In this work, to understand the sand retaining mechanism furtherly, we conducted series of experiments to investigate the microcosmic behavior of screen media with highly argillaceous fine sand samples, and analyzed the retaining and plugging performance and permeability changing law. This research will provide help to make reasonable decision on sand control design with gas hydrate depressurization production.

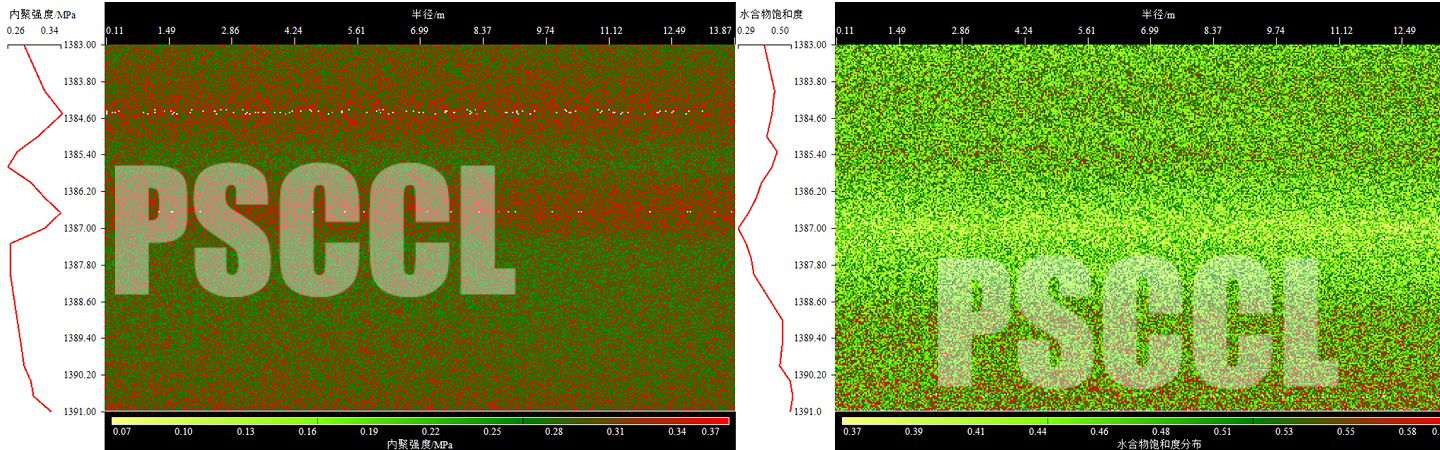

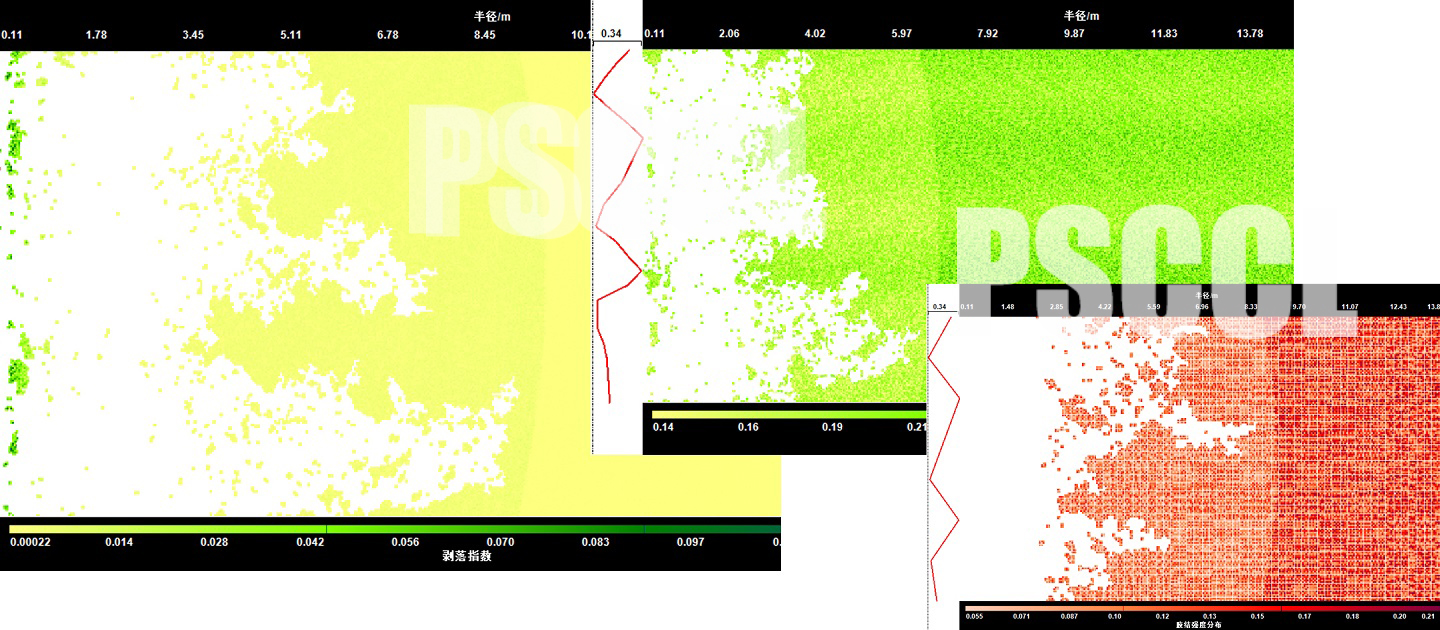

The formation sands of some natural gas hydrate reservoirs in the South China Sea are fine silty sands with high clay content, and it is difficult to mine sand control. Aiming at the problem of high muddy fine sand retaining mechanism, a muddy fine sand sample with a median particle size of 10.13μm was used to simulate the flow conditions of unidirectional gas-liquid sand carrying. Wire-wrapped sieve plates, metal sintered mesh, metal fibers, pre-filled ceramsite, the four types of sand retaining media were subjected to sand retaining simulation experiments with an accuracy of 20-80μm. The microscopic imaging system was used to observe the dynamics of sand particle deposition and blockage inside and on the surface of the sand retaining medium, and to analyze the medium flow performance and sand retaining performance changes. Sμmmarize plugging law, micro-sand retaining mechanism and morphology and its controlling factors. The results show that the blockage of argillaceous fine sand by different types and accuracy of sand retaining media generally shows three stages: the beginning of the blockage, the increase of the blockage, and the blockage balance. As the displacement progresses, the permeability of sand retaining medium will gradually decrease, and the range will reach more than 90%. At the same time, the sand passing speed will slow down and the final sand passing rate will be about 5-10%. According to the plugging law and microscopic image analysis, three types of micro-sand retaining mechanisms for argillaceous fine sand, such as coarse component sorting bridge, moderate sand mass blocking, and overall sand bridge retaining, are proposed. Under the sand retaining conditions where the coarse component sorting bridge is mainly used to retain the sand, the permeability of the sand retaining medium is higher, but the sand passing rate exceeds 15%, and the sand retaining effect is poor. When the overall sand bridge retaining mechanism appears, the sand passing rate is below 10%, and the sand retaining performance is good, but the plugging permeability of various sand blocking media is less than 1μm2, and the flow performance is poor. When the moderate sand retaining mechanism is prevailing, the sand retaining performance and the flow performance of medium are between the other two. The micro-sand retaining mechanism and morphology of sand retaining media on argillaceous fine silt in natural gas hydrate reservoirs are controlled by factors such as the type of sand retaining medium, accuracy, formation sand characteristics, and flow conditions. The law has guiding significance for the optimization of sand controlling.