PSCCL is equipped with series of experimental apparatus involving sand production simulation, sand control optimization, sand carrying simulation, frac-pack well stimulation, integrity evaluation. the laboratory employs apparatus more than 20 installations with 300 m2. The laboratory has the full ability to accomplish the experiments on sand control and fluid-solid management. PSCCL construct united laboratory with CPOE and COSL.

PSCCL employs the following experimental apparatus:

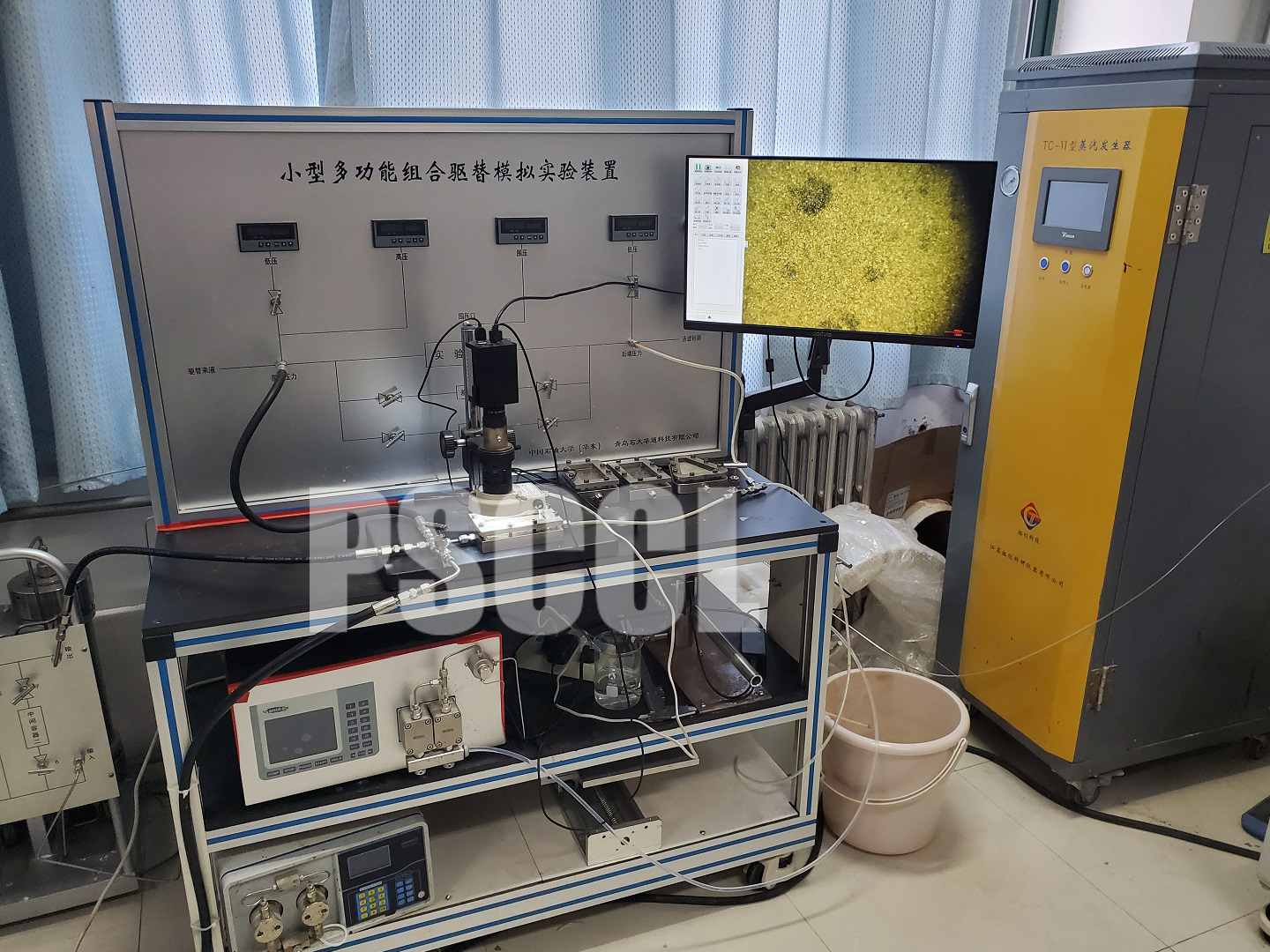

1. Microscopic visual thin-pate sanding simulation apparatus

2. Core-scale sanding displacement system

3. Media-size visual sanding simulation system

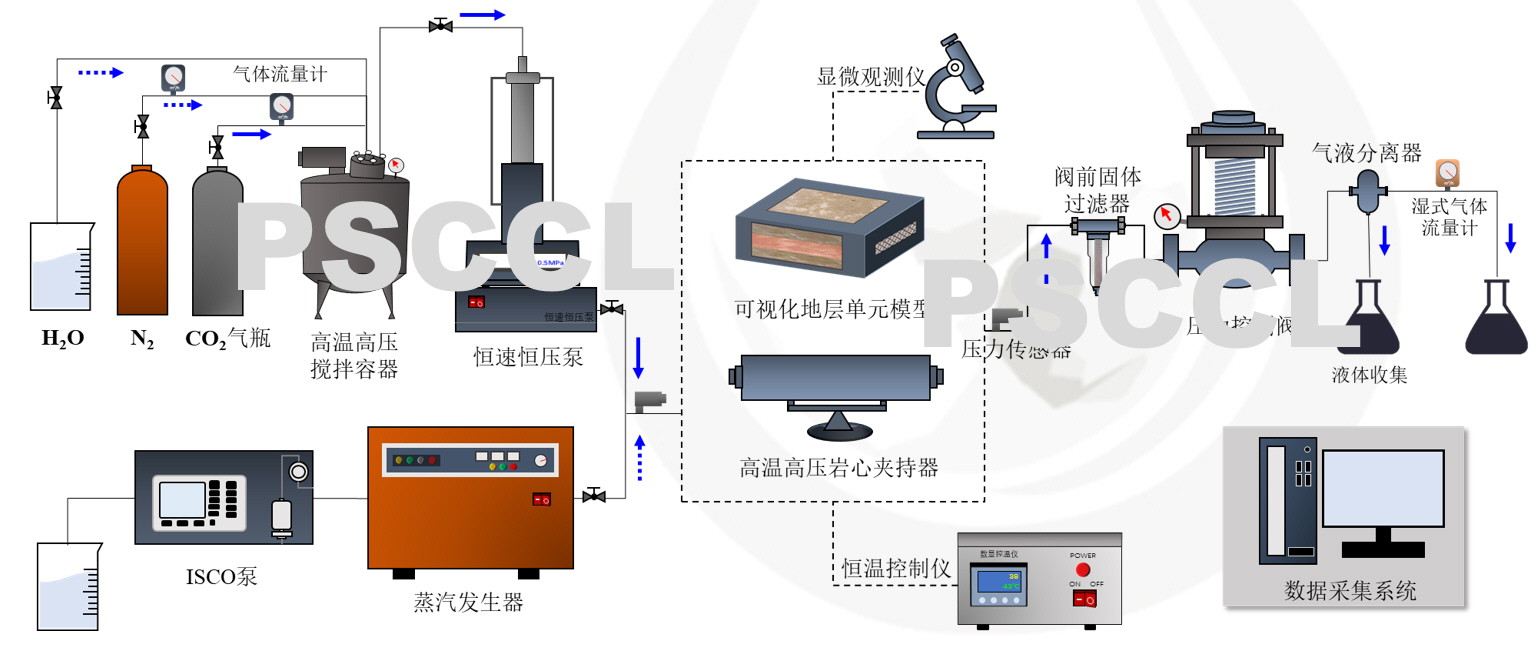

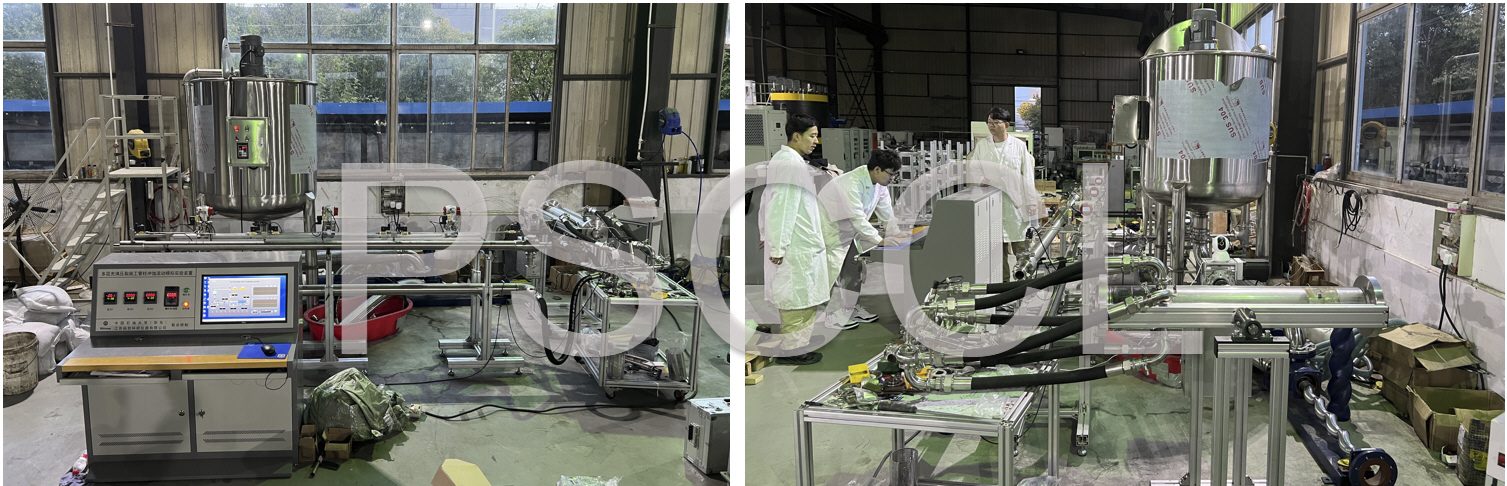

4. Harsh conditions (CCUS/NGH) sanding simulator

5. Large-scale radial flow sanding and control system

6. Visual sand-retaining simulation and evaluation system

7. HTP sand-retaining simulation and evaluation

8. High-pressure and long-term sand retaining simulator

9. Outside-casing squeezing pack simulation system

10. Horizontal gravel-packing, production, sand-water control system

11. LSR Frac-pack initialization and extension simulation system

12. LSR Frac-pack proppant flow-back and control simulator

13. Multi-phase wellbore flow system with sand and solid

14. Screen erosion test and evaluation system

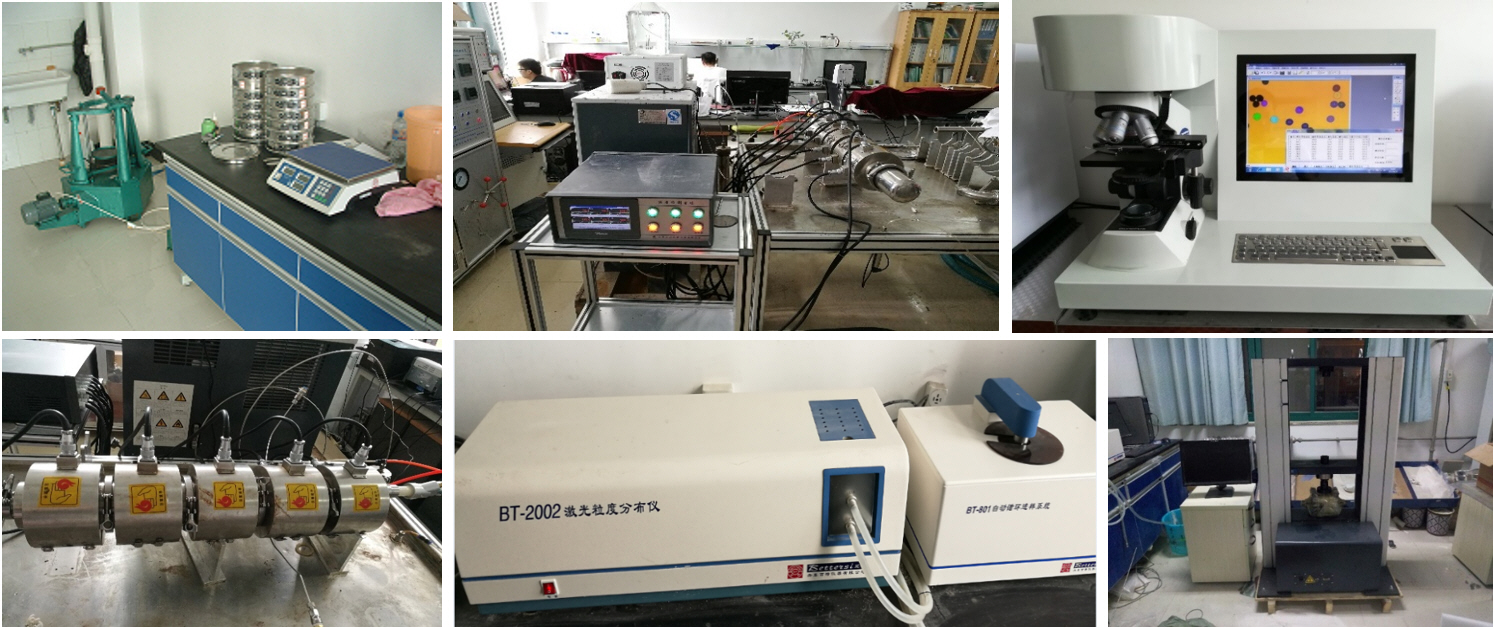

15. HTP Screen corrosion test and evaluation apparatus

16. Solid and fluid properties test and analyze devices

| ▋▎Sanding and Water Production Simulation Experiments Group |

|

1. Microscopic visual thin-pate sanding simulation apparatus |

This setup Visually simulate the sanding process of man-made thin core, to investigate the sanding pattern and left cavities(China patent NO. ZL201710931454.4).

2. Single/alternative core-scale sanding displacement system

Using actual core to teste sand pattern and critical flow condition, which can simulate one-direction flow and alternative injection-production flow for UGGS conditions.

3. Media-size visual sanding simulation system with wellholes Using man-made media size core to visually simulate the sanding process and flow filed around simulated vertical/horizontal and branch well. The container can withstand high pressure of 30MPa.

4. Harsh conditions (CCUS/NGH) sanding simulator (under construction) The container can simulate sand production of thermal steam alternative injection and production, CO2/CCUS process, natural gas hydrate production. The fluid provider can produce gas, water, steam, CO2 and other source fluid.

5. Large-scale radial flow sanding and control system This large-scale radial flow system can be used for sanding and sand retaining process, also can provide alternative injection-production flow condition for UGGS or geothermal water well.

|

| ▋▎Sand Retaining and Water Control Simulation Experiments Group |

|

6. Visual sand-retaining simulation and evaluation system Visually simulate the process of sand retention of different sand control styles, and quantitatively evaluate the sand retaining ability, anti-plugging ability and flowability of sand control medias.(China patent NO. ZL201110151970.8)

The equipment could be utilized on radial flow sand control displacement, and the aim is on screen evaluation and the performance of gravel layer. The functions are exhibited as below: (1) To evaluate the circulation property, sand-blocking ability and anti-clogging property in sand control screens. (2) To evaluate the circulation property, sand-blocking ability and anti-clogging property in gravel layers (3) To evaluate flowing pressure drop in resistance layer as gravel layer inside the screen, perforation holes in gravel layer and the screens. (4) To simulate combined conditions including perforation, open hole, sanding screen sand control and gravel fillup sand control. (5) Other test and evaluation functions. |

7. HTP sand-retaining simulation and evaluation This apparatus is specially designed for sand control simulation and evaluation under the conditions of high pressure and high temperature, thermal production in heavy oil reservoir. It can conduct the test of high pressure of 360℃ and high pressure of 5MPa, with steam flood and steam soak production, also with other complex and high-viscosity fluid.

8. High-pressure and long-term sand retaining simulator

This simulator can be used to simulate the sand retention of screen, prepacked-screen with or without annular packing. It can withstand maximum pressure of 30MPa, which permit to perform the displacement for very long time to simulate the whole process of sand control.

9. Outside-casing squeezing pack simulation system This installation is used to simulate the outside-casing squeezing pack in to the formation with sanding cavities, which can provide visual investigation of packing pattern, volume and performance for –gravel-pack optimization.

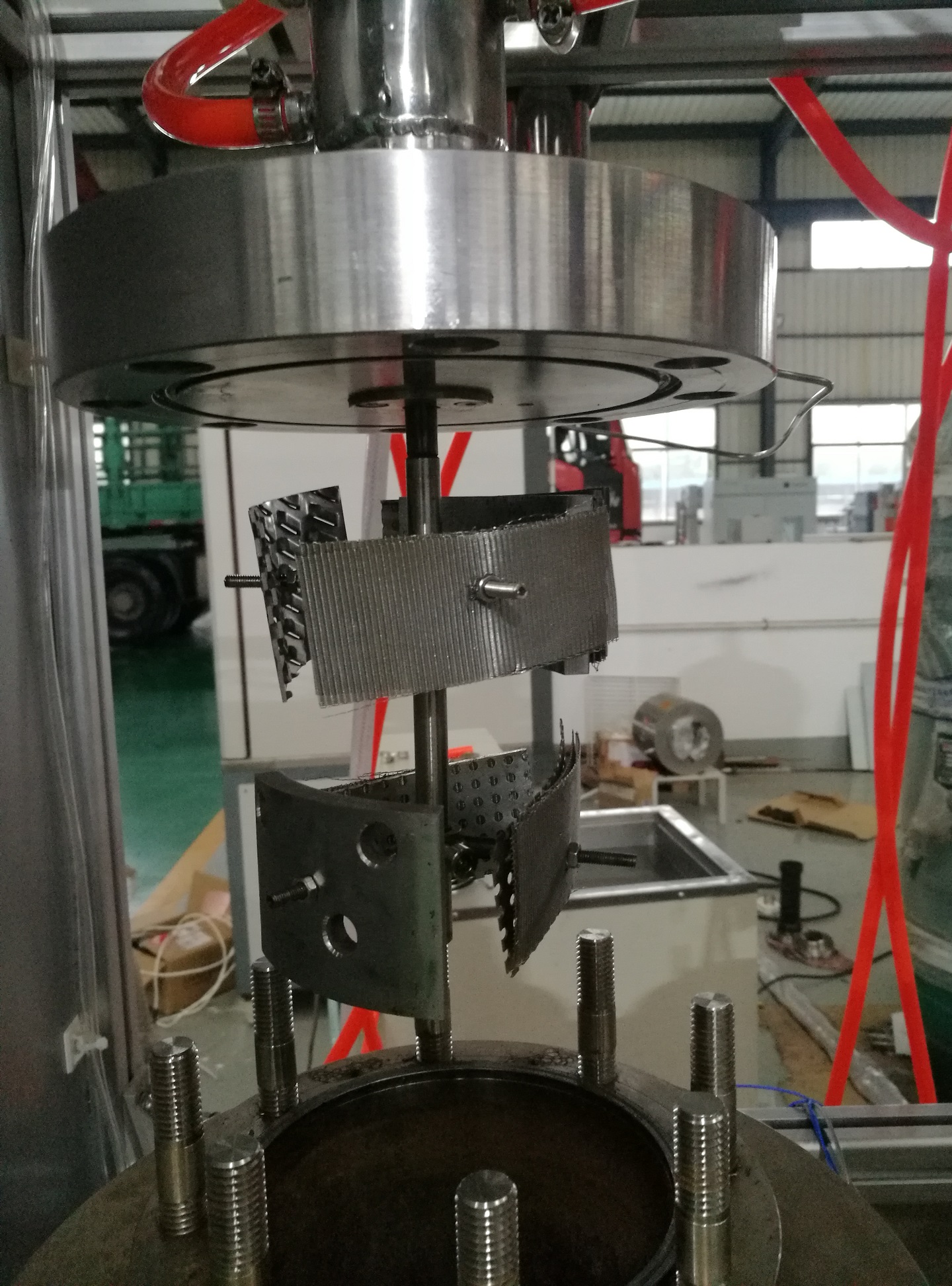

10. Experimental platform for horizontal wells

It is full-size designed as a comprehensive experimental platform for horizontal well sand control, water control and production. It involves key parts of full-size transparent wellbore and formation unit, coupled together to simulate job and production performance of horizontal well system.

Large scale simulation platform of sand-fluid production profile evolution in heterogeneous reservoir(China patent NO. ZL202010233182.2)

Sand control simulation and evaluation system for high TP and thermal oil production The equipment is made to observe and detect the sand-blocking properties of different media, and other functions listed below: (1) Observe the micro sand-blocking and screening process and analyze the principles. (2) Measure the sieve-opening sine and anti-clogging property of screening media.; (3) Measure the flowing pressure drop of different media. (4) To optimize sand-blocking parameters through experiment. |

Real-scale branch well gravel-packing simulation system The experiment equipment is a full-size simulation device, mainly applied on indoor simulation process of gravel filling up in deviated well. During the experiment, the changing condition of fillup process and α wave bed height prediction could be obtained under varied parameter situation such as wellbore inclination, sand ratio, filtration strength and so on. At the same time, the impact of gravel fillup principle in deviated well, different inclination angle and pumping parameters on dynamic filling state and performance would be studied profoundly. The equipment could be applied on parameter optimization and dynamic state control in high-deviated well, and offer technical support for on-site planning and construction. |

| ▋▎Frac Packing Simulation Experiments Group |

|

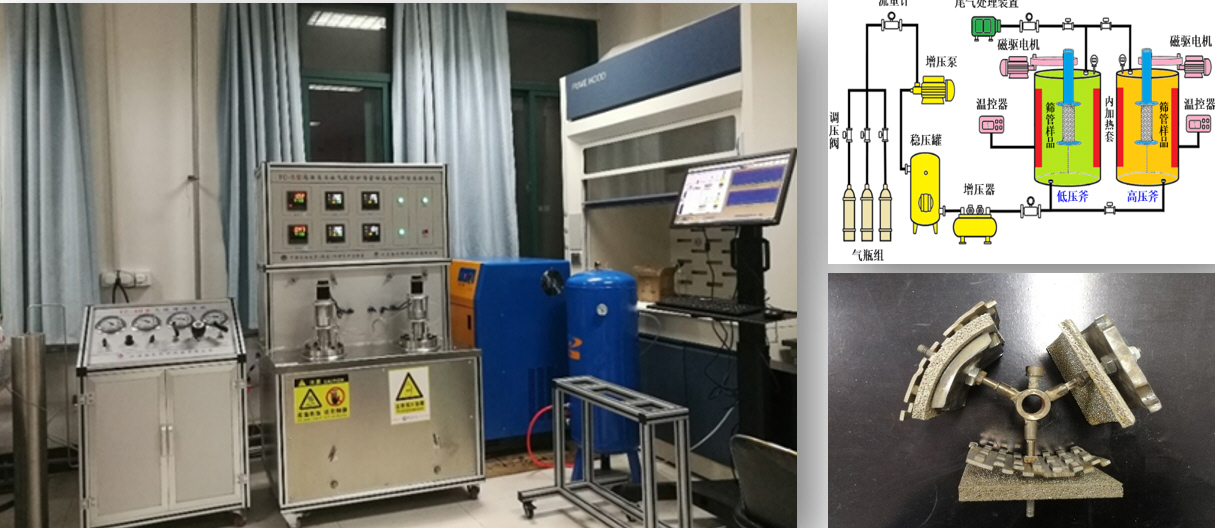

11. LSR Frac-pack initialization and extension simulation system This system is for Frac-pack initialization and extension simulation with triaxial stress, using man-made weakly-consolidated core.

Core size of 200mm×200mm×200mm

Separated imposed triaxial stress of maximum 30MPa and 972KN

Maximum pumping pressure of 70MPa, highest fluid viscosity of 200mPa.s

12. LSR Frac-pack proppant flow-back and control simulator This simulator is used to simulate the process of production after frac-pack. It involves formation section and fracture unit, with preseted fracture close stress. The tests concern proppant flowback, fracture conductivity under compression, proppant embed and sand plugging.

|

| ▋▎Well String Integrity Evaluation Experiments Group |

| 13. Multi-phase wellbore flow system with sand and solid This installation aims at the wellbore multi-phase flow in gas or oil well with sand production, concerning gas-water, gas-water-sand, and other complex flow. The system includes manifolds for vertical well and horizontal well. Transparent body permits to observe visually the flow pattern and sand flowing behavior.

With transparent simulation wellbore, the equipment could be used to study gas-liquid-solid three phase flow characteristics indoor. By observing and measuring, the stability, sand-carrying ability and fracture in different phases would be obtained. In this way, the purpose of formulation optimization, drilling hydraulic calculation and planning will be fulfilled. The functions are presented: (1) To conduct single phase flow experiments like gas and liquid, and measure flowing pressure drop. (2) To conduct double phase flow experiments as gas-liquid, gas-solid and liquid-solid, to observe flow pattern and measure flowing pressure drop. (3) To conduct gas-liquid-solid three phase flow experiment, to observe flow pattern and measure flowing pressure drop. (4) To conduct gas/liquid sand-carrying experiment, and measure critical sand-carrying gas/liquid volume and maximal sand volume with determined gas/ liquid volume. (5) To conduct sand-carrying principle experiment with gas-liquid fluid mixture.

14. Screen corrosion test and evaluation system This container is can house actual component and short joint of metal screen to test the corrosion rate. It can handle temperature of 365℃ and Pressure of 50MPa, and exchange fluid without shut-off. Also, PSCCL proposed an integrated method to process the tested data for erosion evaluation of complicated samples.

15. HTP Screen erosion test and evaluation apparatus This system is used for screen erosion evaluation in vertical and horizontal well with sand production. The set concerns single/multi nozzle erosion simulation in seal space similar to actual well bottomhole. The flow rate, sand ratio, flow distance, flow angle can be adjusted freely.(China patent NO. ZL201811481487.4)

16. Gravel/Frac-pack job tubing erosion failure test and evaluation This system is specially constructed for Erosion damage simulation of lateral holes in multi-layer frac-packing operation string. It contains main container for the test tools, pump, fluid and proppant tank and data collection and processing system. It’s mainly used for erosion damage law of lateral holes.

|

| ▋▎Other Testing Devices |

|

|

|

Welcome to visit PSCCL WeChat platform:

|